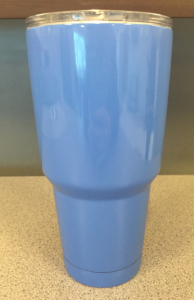

I want to b rief this post by telling you something about me: I’m a bargain hunter. I cringe at the thought of paying full price for almost anything. I get this honest as my parents own a consignment shop and some of my fondest childhood memories were spent shopping for deals at Goodwill with my granny. I recently had the desire to buy one of those nifty stainless steel cups that holds ice for hours, but paying a steep price wasn’t in the game plan. I came across one of these cups online at a price my wallet loved and decided to purchase one in blue. The cup was coming from China, and as it was en route to my doorstep I began getting concerned about lead in the paint used to color the cup.

rief this post by telling you something about me: I’m a bargain hunter. I cringe at the thought of paying full price for almost anything. I get this honest as my parents own a consignment shop and some of my fondest childhood memories were spent shopping for deals at Goodwill with my granny. I recently had the desire to buy one of those nifty stainless steel cups that holds ice for hours, but paying a steep price wasn’t in the game plan. I came across one of these cups online at a price my wallet loved and decided to purchase one in blue. The cup was coming from China, and as it was en route to my doorstep I began getting concerned about lead in the paint used to color the cup.

However, I knew there was no need to fret – I work in a materials testing lab! On Monday morning I took my cup to Jarret Wright, our thermal, physical and microscopy lab manager. I explained to him my concern and he said we could use x-ray fluorescence spectroscopy (XRF) to unlock the answers to my lead concern. I was excited that soon I would have answers, and in the process learn more about the cool science happening in our labs every day.

Lead exposure can lead to a variety of health problems. Fortunately, lead in products is something heavily regulated in the United States. However, countries like China do not have strict regulations, and according the Pure Living 34 percent of children living in China have a blood-lead levels that exceed the WHO limit. Some of the many side effects of lead exposure in adults are hearing loss, fatigue, nausea and anemia (the list goes on). After researching all of this I realized I had the right to be concerned.

I waited all day a s my cup sat on my desk staring back at me. I didn’t want it to be true; I didn’t want the paint that coated my new cup to have lead in it. At 4:00 PM Jarret popped in my office with the XRF. To me, it looked like an oversized scanner you’d see at a retail store, but that’s aside the point. XRF works by measuring the characteristic x-rays emitted from a sample after it has been bombarded by high-energy radiation. This measures the energy and quantity of the emitted x-rays, making it possible to determine which elements are present in a sample. Jarret held the device to my cup for 90 seconds as I patiently watched (and snapped pictures for this blog). Before I knew it he was done. The results were that if my cup contained any lead, it was below the legal limit allowed in medical devices in the United States. Jarret assured me my new cup was safe to drink from.

s my cup sat on my desk staring back at me. I didn’t want it to be true; I didn’t want the paint that coated my new cup to have lead in it. At 4:00 PM Jarret popped in my office with the XRF. To me, it looked like an oversized scanner you’d see at a retail store, but that’s aside the point. XRF works by measuring the characteristic x-rays emitted from a sample after it has been bombarded by high-energy radiation. This measures the energy and quantity of the emitted x-rays, making it possible to determine which elements are present in a sample. Jarret held the device to my cup for 90 seconds as I patiently watched (and snapped pictures for this blog). Before I knew it he was done. The results were that if my cup contained any lead, it was below the legal limit allowed in medical devices in the United States. Jarret assured me my new cup was safe to drink from.

You’re probably reading this thinking “really, all of that for a cup?” And my answer to that is yes, absolutely. Every day I see how labs like Polymer Solutions Incorporated (PSI) better the lives of people through its testing capabilities. Working at an incredible company has sparked my curiosity, and I couldn’t sit at my desk with my cup staring back at me and not know if it was safe.

Unlike the time I shattered a cow cookie jar at a thrift store because it was just so darn cute, this bargain was a win for me. Our scientists experience wins every day by solving problems for our clients in the medical, pharmaceutical, packaging and manufacturing industries. And with all of the cool testing capabilities PSI offers, who knows what we’ll discover next!