Chemical Analysis

The morphology of a material is examined to make structure-property relationships. These are related to processing conditions which effect final product performance.

Metals, composites, and polymers frequently have specifically engineered morphologies and microstructures to achieve specific properties. For these reasons, understanding the structure – property relationships of the material can be critical to predicting how the materials perform. If it is understanding the crystallinity of a medical device after injection molding or examining the phase domains of high impact polystyrene, we can help.

Approaches

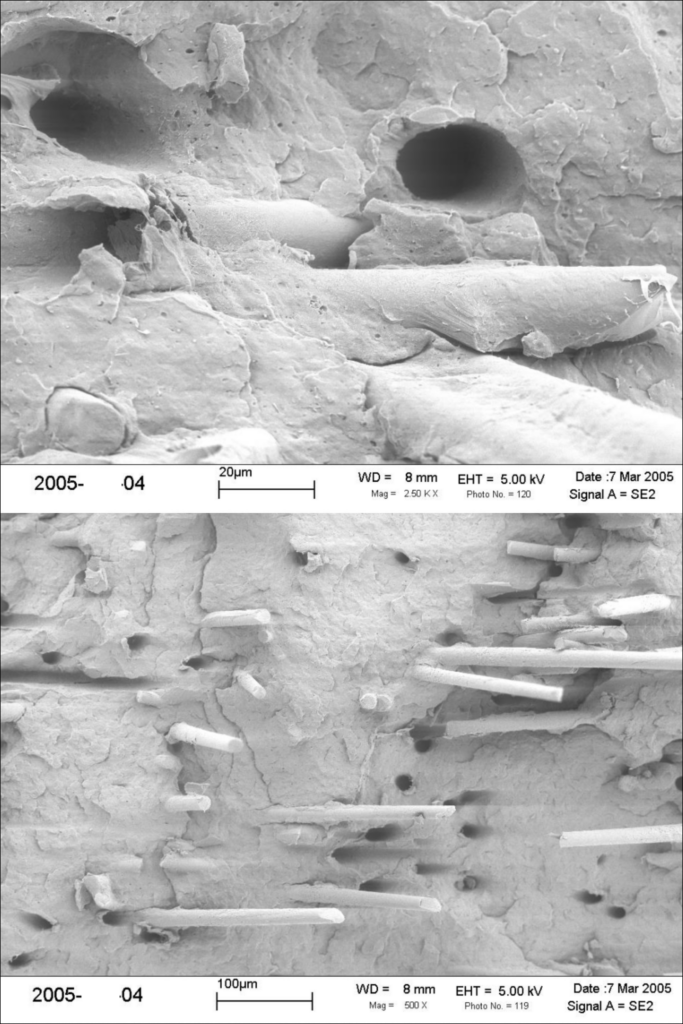

Morphological analysis encompasses multiple different analytical techniques. The analytical methods most utilized by us are SEM and Transmission Electron Microscopy Testing (TEM). These are used for the examination of properties like phase separation and domain size or the failure mechanism of a fractured surface of a glass fiber reinforced polymer. It is most commonly used to examine the surface or cross section of the sample for different features like contaminants, inclusions, or phase separations. Our SEM also has an Energy Dispersive X-Ray Spectrometer which provides the elemental composition of a certain selected area of the sample. This is invaluable for inorganic particle contamination analysis. Both SEM and TEM require meticulous sample preparation to prevent inadvertent manipulation of the microstructure.

These analytical techniques are commonly paired with thermal analyses like DMA , DSC, and TGA and also Physical Testing Methods like tensile, flex, and compression testing. By coupling these analytical techniques, information about structure-property relationships, like the relationship of phase domain characteristics to impact properties of HIPS, can be gathered.

Sample Considerations

For SEM and TEM Analysis, we are able to analyze samples collected from a wide variety of products. These can be films, injection molded parts, resin pellets, or a fractured surface cut from a failed part. We can prepare a smaller representative sample from a larger part and will typically sputter coat non-conductive samples.

Contact us to discuss your testing needs and associated sample considerations.

Experience

- Nanomaterial Dimensional Analysis

- Porosity of Novel R&D Materials

- Phase Dimensions of HIPS by TEM

- Cross Sectional Analysis for Layer Thickness of Multilayered Materials

- Failure Analysis of Various Materials

- Glass Fiber – Polymer Resin Interface at a Fractured Surface