Thermal

Analyze Thermal Behavior with DSC Testing from SGS PSI

Differential Scanning Calorimetry (DSC) is a powerful technique used to measure how materials respond to temperature changes. It identifies key thermal transitions – such as residual cure, solvent evaporation, melting, crystallization, and glass transitions. These insights support product development, quality control, and material selection.

Approaches

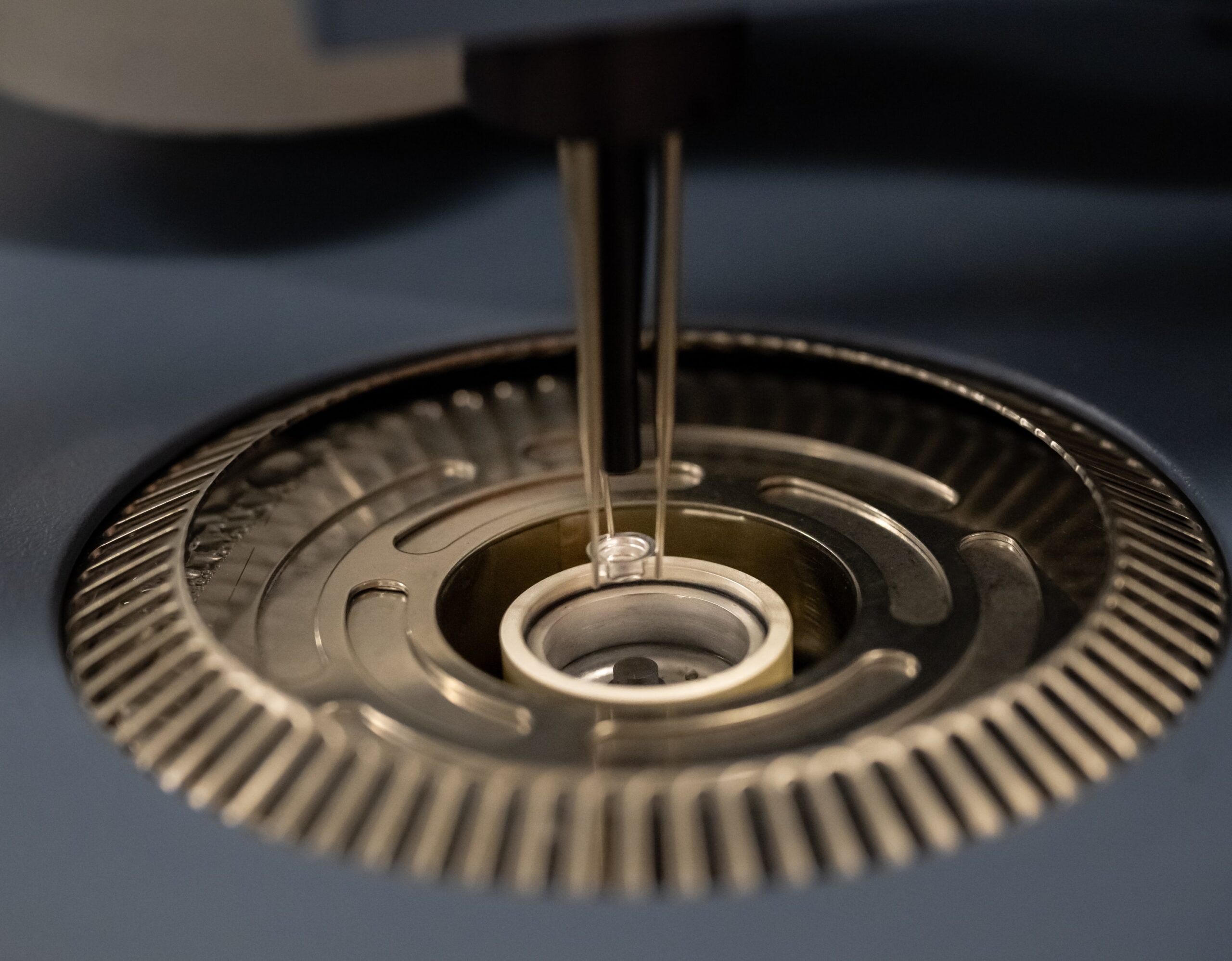

Our laboratory uses thermal instrumentation with integrated auto-sampling, so we can process up to 54 samples in a single run, delivering consistent, repeatable results without delays. Send us your batch, and we’ll handle the rest – streamlining your workflow and accelerating your timelines.

Testing is tailored to your specific protocols. While nitrogen is the typical ambient atmosphere, it can be adjusted as needed. We deliver exceptional sensitivity and precision across a wide temperature range (–80 °C to 725 °C). Heating and cooling rates are precisely controlled – often at 10 °C per minute.

Key Benefits

- Thermal Property Characterization | Accurately measures melting points, crystallization, glass transition temperatures (Tg), heat capacity, and thermal stability.

- Material Identification and Purity Analysis | DSC helps determine material composition and detect impurities by comparing thermal profiles.

- Quality Control & Consistency | Ensures material behavior meets specifications and remains consistent across batches, this is crucial for manufacturing and regulatory compliance.

- Product Development Support | Used in R&D to evaluate thermal performance and optimize formulations, especially for polymers, pharmaceuticals, and composites.

- Rapid, Reliable Testing | DSC tests are fast and require minimal sample preparation, making them ideal for routine screening or large sample sets – especially with an autosampler.

- Non-Destructive Testing | Minimal sample alteration allows for additional follow-up analyses.

Common Standards We Test

- ASTM D3418 (Tg & Tm)

- ASTM E1952 (thermal conductivity by MDSC)

- ASTM E1269 (heat capacity by MDSC)

- ASTM E794 (melting and crystallization temperatures)

- ASTM D3895 (oxidative induction time, OIT)

Experience

- Determination of cure in fiberglass reinforced epoxy products

- Heat capacity of ceramic disks

- Crystallization kinetics of a polymer

- Melt spun fiber products

- Injection molded plastic

- Medical devices

Sample Considerations

DSC testing is applicable to nearly all plastic and rubber materials – including thermoplastics, thermosets, and elastomers – along with a wide range of other materials.

A typical polymer sample weighs about 10 milligrams and metal samples can be up to about 40 milligrams due to their higher densities. From a size perspective, a “perfect DSC sample” is a quarter inch diameter disk approximately 1 mm thick. The sample must remain in the sample pan so special considerations are required if the sample can foam during the heating cycles.

Contact an expert to discuss your specific testing needs and associated sample considerations.