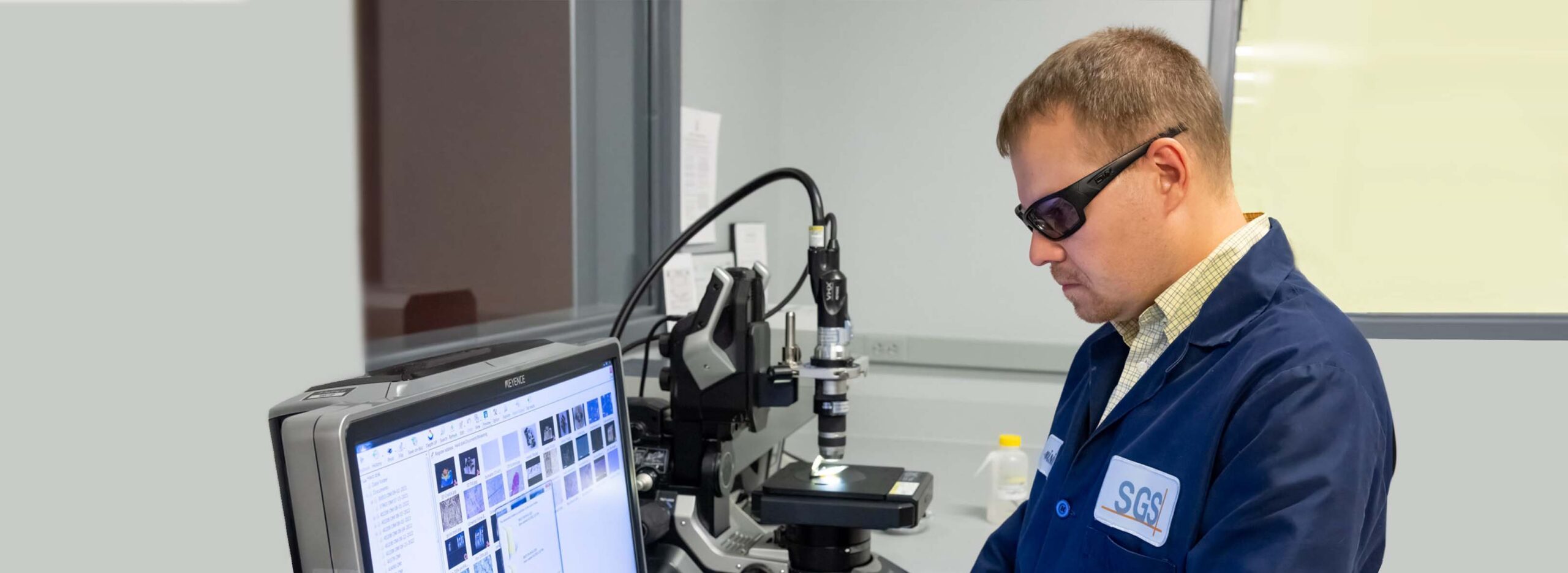

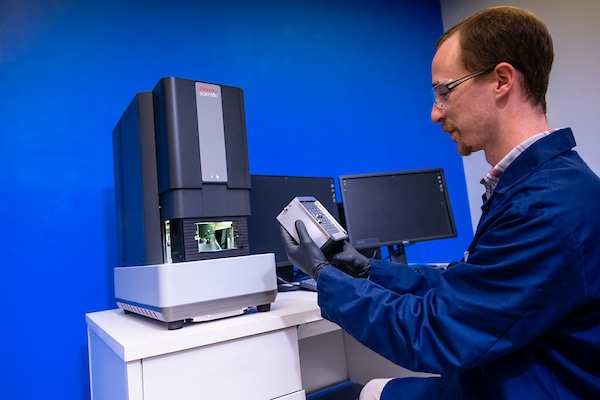

Microscopy

The morphology of a material is examined for structure-property relations to correlate processing conditions and final product performance.

Metals, composites, and polymers frequently have specifically engineered morphologies and microstructures to achieve a desired yield strength, impact strength, hardness, corrosion resistance, or other physical properties. Understanding the structure – property relationships can be critical to predicting how materials will perform. We can assist with understanding the structural properties of a medical device after injection molding or identifying and characterizing the layers of high-performance film.

Approaches

Morphological analysis encompasses multiple analytical techniques. We commonly use SEM and TEM for characterization of the microstructure of materials. Both methods require meticulous sample preparation to prevent inadvertent alteration of the microstructure. If your sample requires a different method, our scientists would be happy to work with you to select the appropriate methods.

Our Scanning Electron Microscope, coupled with our Energy Dispersive X-Ray Spectrometer (SEM/EDS) can be used to determine the microstructure morphology and confirm the elemental composition of contaminants or inclusions.

For metallic materials, we can chemically etch your sample to identify different phases and grain boundaries and we have experience with chemically staining samples like HIPS for TEM analysis of phase dimensions.

Sample Considerations

For SEM and TEM analysis, we are able to analyze samples collected from a wide variety of products. Samples can be as small as a few square millimeters as long as they are representative. We can prepare a smaller representative sample size from a larger sample and will typically sputter coat nonconductive samples for SEM analysis. Staining is available to increase electron density contrast for TEM analysis. Other methods of probing the morphology and microstructure of samples have varying requirements.

Contact us to discuss your testing needs and associated sample considerations.

Experience

Our team has a wealth of experience related to microstructural analysis related to the size analysis of nanoparticles, the porosity of novel R&D type materials, and the phase dimensions of high impact polystyrene (HIPS) by TEM.