Deformulation

Additive analysis is commonly performed to verify product conformance, analyze competitive samples, assist in failure analysis, or to develop a new product.

Polymers are useful in a variety of applications because of the combination of polymer selection and the additive package that enhances the performance of the product. Without a proper additives package, the polymers may not process well at your facility or may not meet the needs and requirements of your customers or end users. Additives are commonly used to assist with environmental exposures such as heat, oxygen, ozone, radiation, solvents, water and stress.

Approaches

Typically, additives analysis is done to verify product conformance to a formula, compare competing products, determine cause of failure, or guide a development program. We can customize the testing and project to your specific needs and your specific resin or product.

We analyze the following:

- Plasticizers

- Heat stabilizers

- Antioxidants

- Antiozonants

- Light stabilizers

- Reinforcing fillers

- Impact modifiers

- Other fillers and additives

Sample Considerations

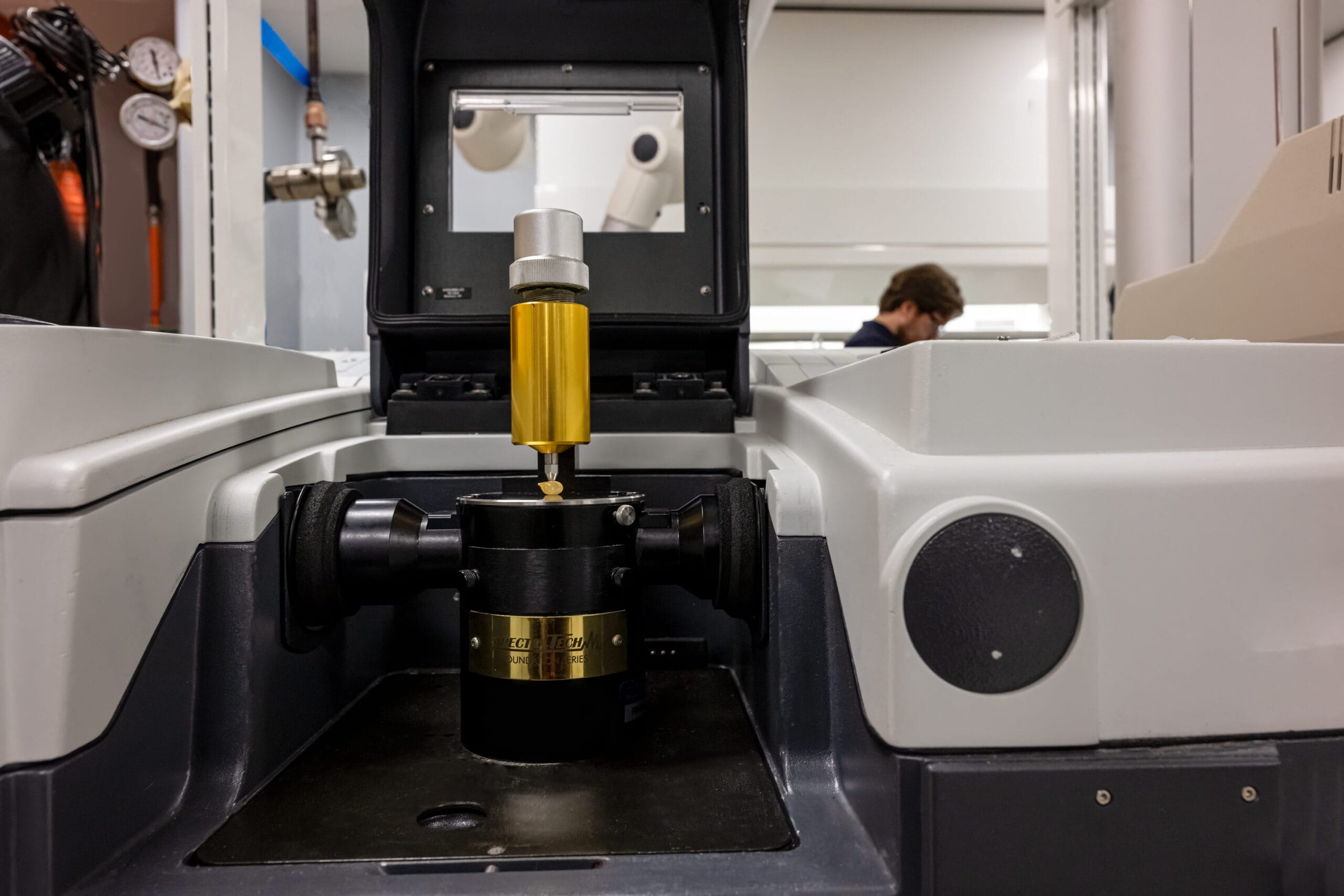

Organic additives are extracted from the sample with an appropriate solvent and then analyzed using chromatography to separate the mixture of additives and a spectrometer to provide identification. Gas Chromatography (GC) and Liquid Chromatography (LC) are often used.

Inorganic additives can be evaluated using either ICP or Energy Dispersive Spectroscopy. Since the EDS is part of our SEM, we additionally acquire images to determine particle size and shape after the appropriate sample preparation Contact us to discuss sample considerations specific to your testing needs.

Experience

Products we’ve tested:

- Medical products

- Packaging materials

- Construction materials

- Agricultural products

- Electronic components