Physical

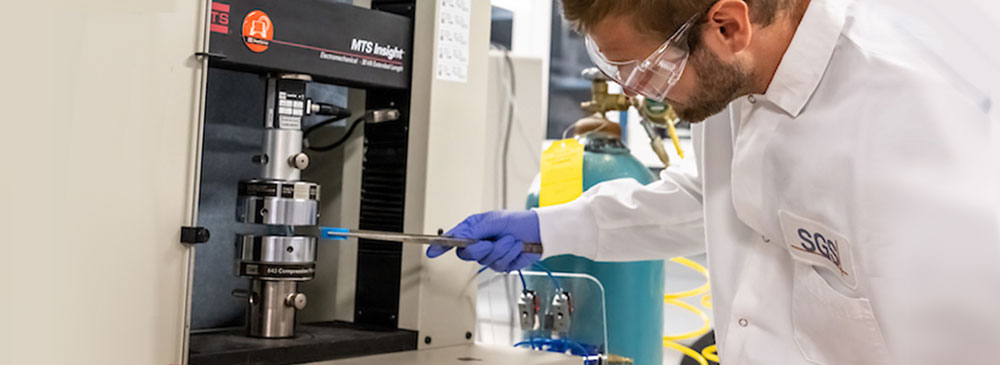

Tensile tests measure the tensile force required to stretch, yield, and fracture a material and the extent to which the material elongates to the yield or failure point.

Approaches

Tensile testing is often used as a quality control check of the material or parts. It is also used frequently as input during the design phase of a material or molded product. Tensile tests are often used to measure the loss in mechanical strength as a function of use, accelerated aging, or chemical exposure. ASTM Standards:

- D882

- D638

- D412

Sample Considerations

There are unique test protocols used for tensile testing of:

- Films

- Plastics

- Rubbery materials

- Metals

Standard specimens or molded products can also be tested. Contact us to discuss your specific sample considerations with one of our scientists.

Experience

We frequently conduct tensile testing suppliers or consumers as a means of quality control.

Products we’ve tested:

- Slats for lawn furniture

- Multi-layer packaging films

- Polymer rivets used in bowling machines

- Plastic conduit for electrical cable installations

- Strength of orthopedic anchors in bone and bone simulants