Physical

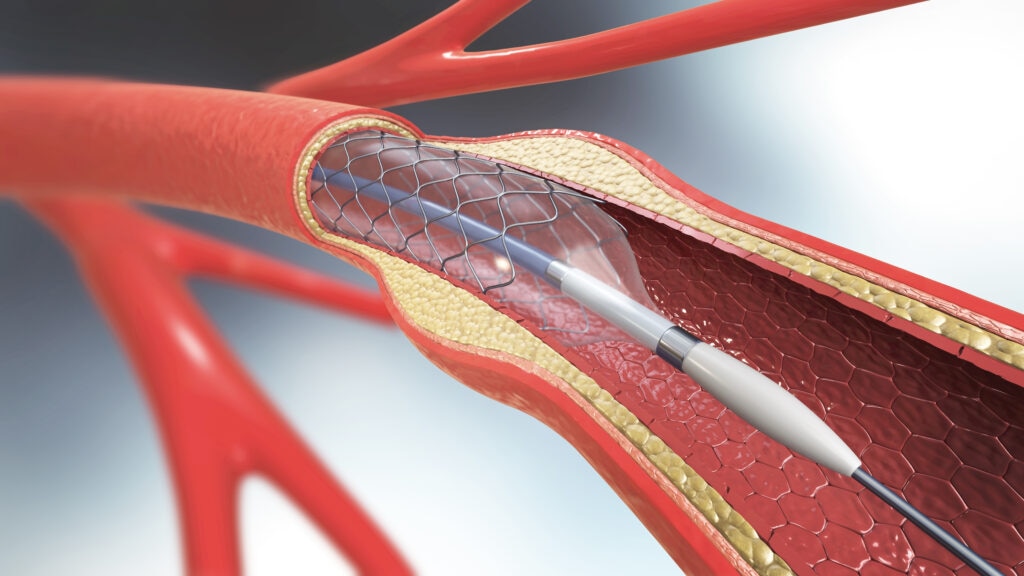

In vitro testing can be utilized to predict the rate at which hydrolytically degradable polymers degrade under physiological conditions.

ASTM F1635 (in vitro Degradation Testing of Hydrolytically Degradable Polymer [HDP] Resins and Fabricated Forms for Surgical Implants) assesses degradation rates of devices made from resorbable polymers. The polymers and copolymers covered by this method are composed of L-lactide, D-lactide, D,L-lactide, glycolide, caprolactone, and p-dioxanone. Degradation rates can be greatly affected by exact composition, specimen size, polymer molecular weight, and crystallinity.

Method Specifics

Mechanically loaded and unloaded hydrolytic evaluation is described in ASTM F1635 . Unloaded mechanical hydrolytic evaluation is often performed to obtain a baseline profile of the polymer. Mechanical loading may be considered if loading will be encountered in vivo. We can work with you to determine the best approach.

Devices that are subjected to flow conditions while in use may have a different degradation rate than other devices. Most commonly, the buffer is kept in a static state, but we can develop methods for flow during the aging if needed.

Sterilization of resorbable material may cause changes in mechanical and molar mass properties. This could affect the base-line testing. For this reason, specimens should be sterilized and packaged as in actual use. Non-sterilized specimens may be tested for comparative results.

Phosphate buffered saline (PBS) is typically used as the soaking solution and maintained at a pH of 7.4 unless it has been documented that the pH should be different in the specific device and its use. Bovine serum may also be used as the solution.

PBS to HDP ratio is generally selected to be as high as is practical to prevent excursions in pH. 100 to 1 is a common choice. Multiple samples may be stored in the same container as long as suitable sample separation is maintained. A minimum of three samples are usually tested per time period.

Test Methods

Testing typically include mass loss, molar mass, and mechanical testing, but is customized to the needs of the client.

For many HDP resins, inter-lot variations in molar mass and residual monomer can be significant. This can affect degradation rates. It is recommended that the residual monomer of the parts be analyzed.

Molar Mass can be evaluated by solution viscosity or size exclusion chromatography (SEC).

pH of the PBS is most commonly tested at least once per week

Weight loss is usually measured to a precision of 0.1% of the total sample weight. Samples are frequently dried to a constant weight prior to the start of aging.

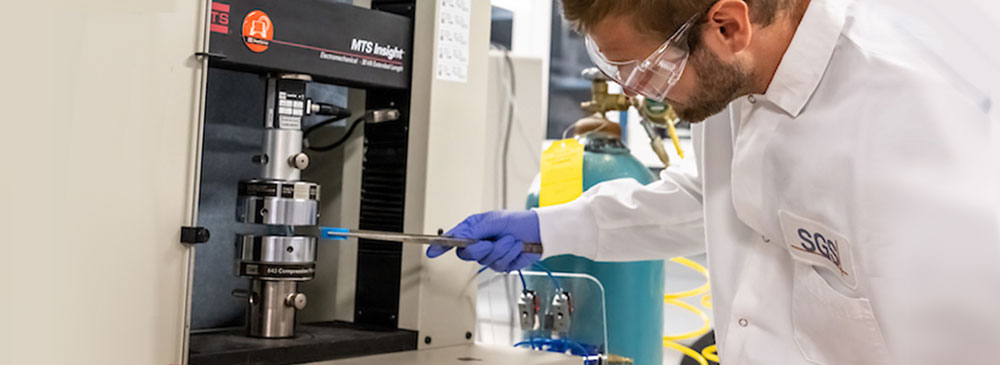

Mechanical test methods will be chosen from the following (other methods may be included):

- ASTM D638 Standard Test Method for Tensile Properties of Plastics

- ASTM D695 Standard Test Method for Compressive Properties of Rigid Plastics

- ASTM D790 Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

- ASTM D882 Standard Test Method for Tensile Properties of Thin Plastic Sheeting

- ASTM D1708 Standard Test Method for Tensile Properties of Plastics by Use of Microtensile Specimens

Testing Termination

Test termination is usually defined by one of the following:

- A predetermined time point has been reached

- Sample integrity has been compromised to the point that samples can no longer be tested or the data are no longer meaningful

- The solution has drifted outside the pH range of 7.2-7.6