Microscopy

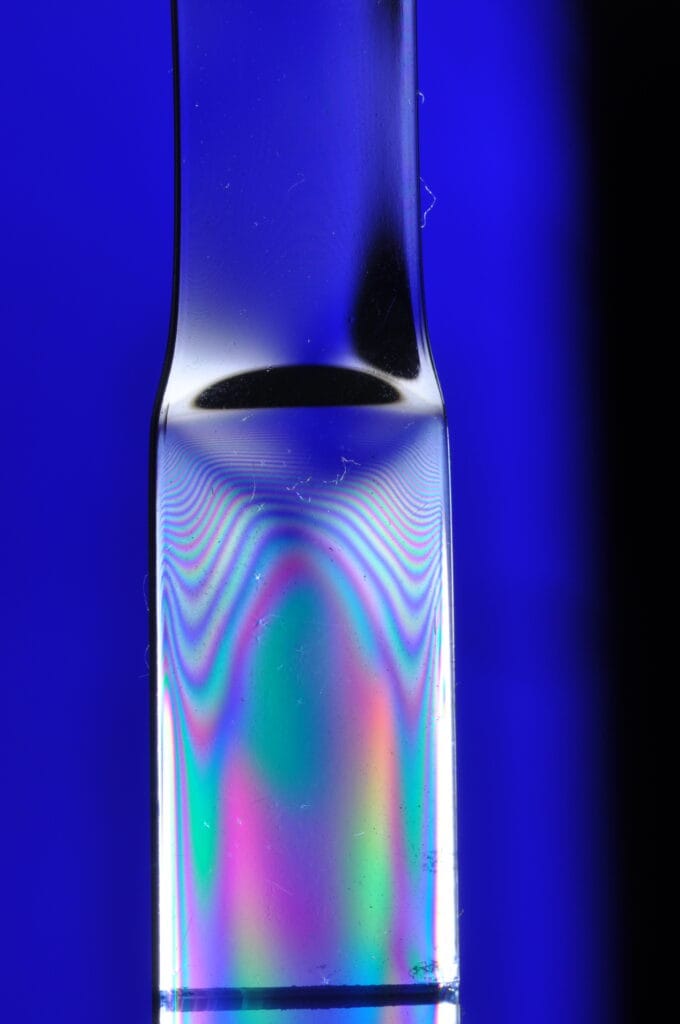

Optical birefringence provides an image with spaced colored zones that relates to the stress distribution that exists within the sample that is positioned between light polarizers.

Optical birefringence allows for a non-destructive qualitative assessment of residual or molded-in stress of transparent materials and parts by examining a sample between cross polarizers.

Approaches

The analysis can be performed on large parts or with small parts under magnification.

Many plastic parts are transparent which enables this analytical method to be applied to numerous types of injection molded, compression molded, or extruded plastic parts.

It is common to compare an “as-produced” part with an annealed part to verify the effectiveness of the post-processing parameters.

Birefringence can be coupled with hot stage microscopy to determine the melting point of a sample material or component. This can also be used to distinguish between different layers of a transparent film.

Sample Considerations

To be able to perform Optical Birefringence Analysis the sample must be optically transparent.

Please contact an expert with your specific sample consideration questions.

Experience

Work we’ve done:

- Part design

- Failure Analysis

- Functional testing

- Assessment of residual stress in a material

- Assessment of molded in stress

- Evaluate stress points in a material due to an external force

- Evaluate areas of high or uniform stress

- Monitor annealing process