Medical Device Testing

Chemical resistance testing, exposure testing, and aging studies can be performed proactively or in response to a failure analysis investigation.

Although much testing is done after the fact to determine the cause of material failures, chemical resistance testing and aging studies can also be performed proactively. Appropriate analytical protocols can be used to objectively assess the response of materials to relevant aging conditions and chemical exposure. Included with aging is long term storage, exposure to radiation (sterilization, UV light), and the effects of prolonged high temperature or humidity exposure.

Approaches

Long term exposure of medical devices and components to physiological conditions can alter the physical properties of materials. Our scientists have performed aging studies on medical products using protocols that simulate physiological conditions.

Thermal aging has also been conducted to advance industrial programs.

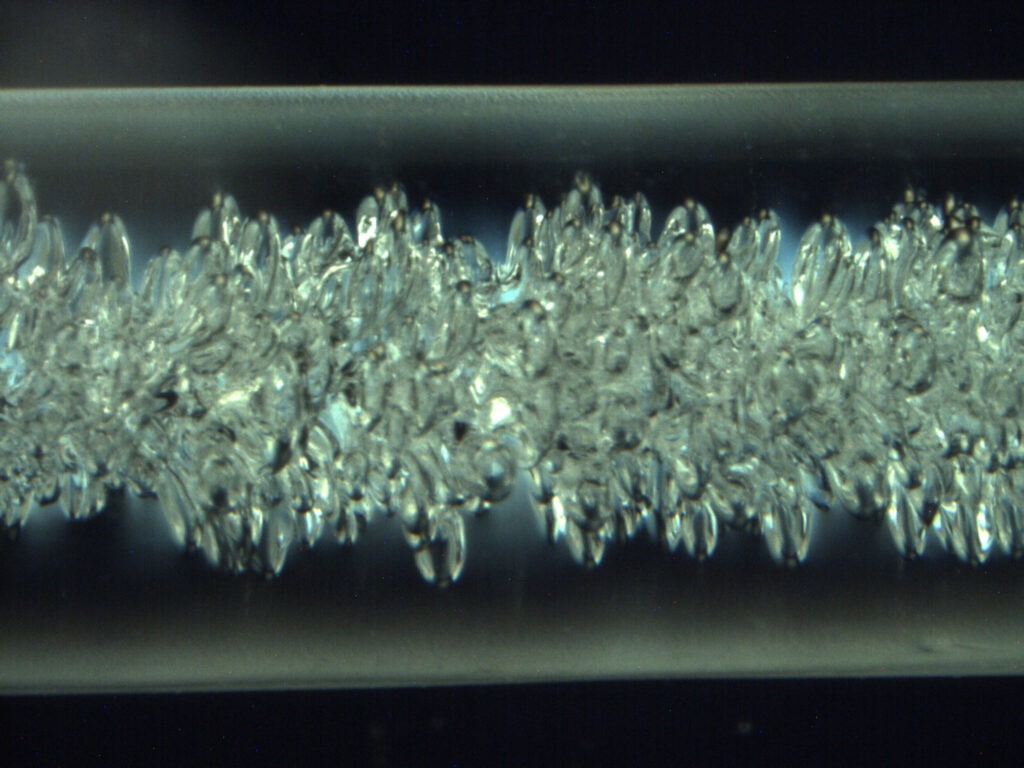

Stress in combination with chemical exposure can cause environmental stress cracking.

The tolerance of and response to certain chemicals has been determined for many different polymer materials, including chlorinated polyvinyl chloride.

Sample Considerations

It is common to require a fairly large amount of sample materials to perform aging and chemical resistance testing because the exposure protocols typically include several timepoints or conditions with multiple tests on replicate specimens.

Our scientists will work with you to establish the protocol, which includes a determination of the specific sample requirements.

Contact us to determine the specific sample requirements for your testing needs.

Experience

Products we’ve tested:

- Plastic pipe

- Automotive components

- Rubber products

- Packaging materials

- Medical tubing

- Life safety & fire protection devices

- Food packaging