Failure Analysis

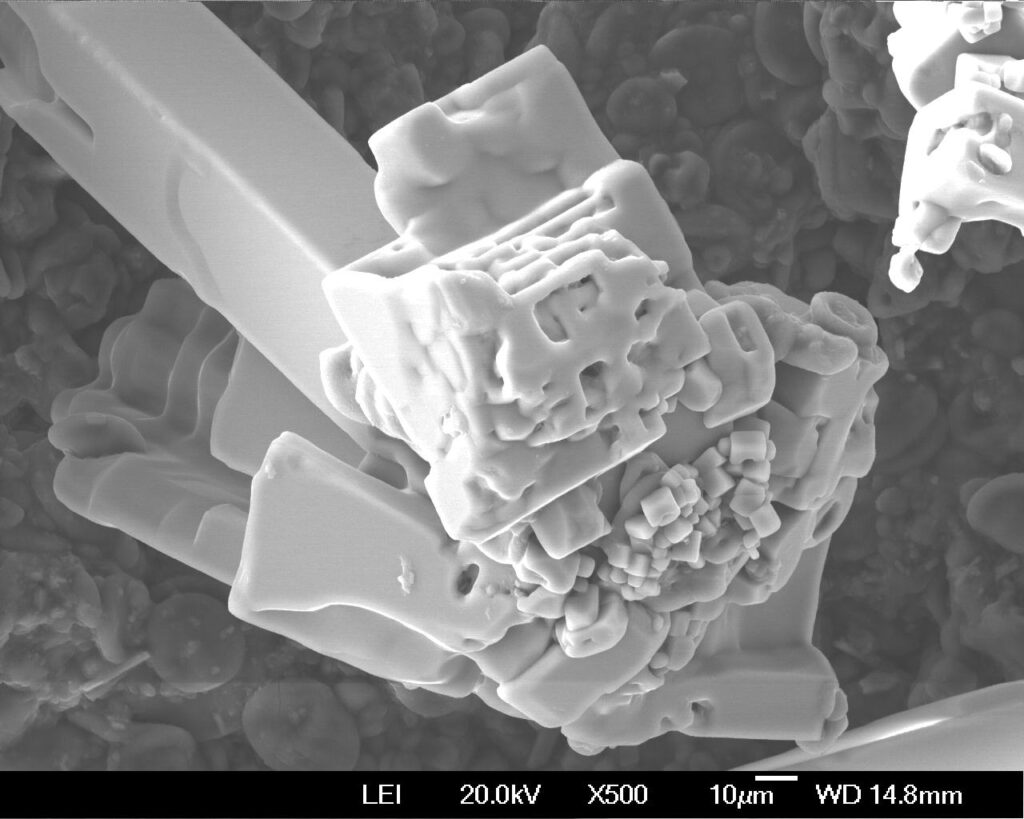

Corrosion usually leaves behind a corrosion pattern and product which can be analyzed with Optical Microscopy and Scanning Electron Microscopy.

Corrosion is an electrochemical reaction which is a common catastrophic failure mode for metallic materials. Corrosion usually leaves behind a corrosion pattern and product which can be analyzed with optical microscopy and SEM/EDS. Common corrosion patterns include: pitting, crevice corrosion, galvanic corrosion, and environmentally induced cracking (EIC). EIC can be stress-corrosion cracking (SCC), corrosion fatigue cracking (CFC), or hydrogen-induced cracking (HIC).

Approaches

Typically we first identify the corrosion product and then we perform sample preparation to aid in determining the mode of corrosion by analyzing the penetrations or other corrosion surface features.

The areas of interest for corroded samples are often at any penetrations or crack surfaces. Crack surfaces and crack edges can both yield information as to the corrosion mechanism, and are examined with microscopy. Metallographic preparation of these areas is performed beforehand to assist with the desired microscopic analysis technique.

In addition, corrosion of metallic materials is often unexpected and usually caused by a combination of electron exchange and mechanical forces. Electron exchange is often accelerated by heat or conductive fluids. Mechanical forces include tension, bending, and shear loads.

To provide a complete and thorough corrosion analysis it is important for our team to have information about the environmental conditions to which the samples were exposed.

Sample Considerations

Samples will range in size from very small to very large, and our team is equipped to handle the full range. Typically large samples will require sectioning in order to be able to analyze the sample with SEM/EDS. Our team will take care of the sample preparation and sectioning for you.

Sometimes corrosion samples need additional metallography preparation before being analyzed with the SEM/EDS. Metallography preparation includes techniques such as cleaning, sectioning, grinding/polishing, and etching samples.

Please contact an expert to discuss your corrosion analysis needs and associated sample considerations.

Experience

Our team of well-educated and experienced scientists include metals and other material experts. We have years of experience with forensic and metallurgical engineering.

Specific examples of corrosion testing we’ve done include:

- Corrosion of stainless steel

- Medical devices

- Corrosion of aluminum rails

- Residential water piping corrosion analysis

- Commercial water piping corrosion analysis