Thermal

Assess Your Polymer’s Rheological Properties and Deformation Behavior Under Stress

Rheology testing is used to understand melt viscosity and flow behavior – key properties that influence how plastics process, mold, and perform in real-world applications. It’s essential for product development, quality control, and troubleshooting in industries like medical devices, packaging, and consumer goods. This testing can reveal:

- Viscosity: How resistant a material is to flow.

- Elasticity: How it stretches or recovers.

- Shear thinning/thickening: How it behaves under stress or strain.

- Temperature time dependence: How flow changes with heat or aging.

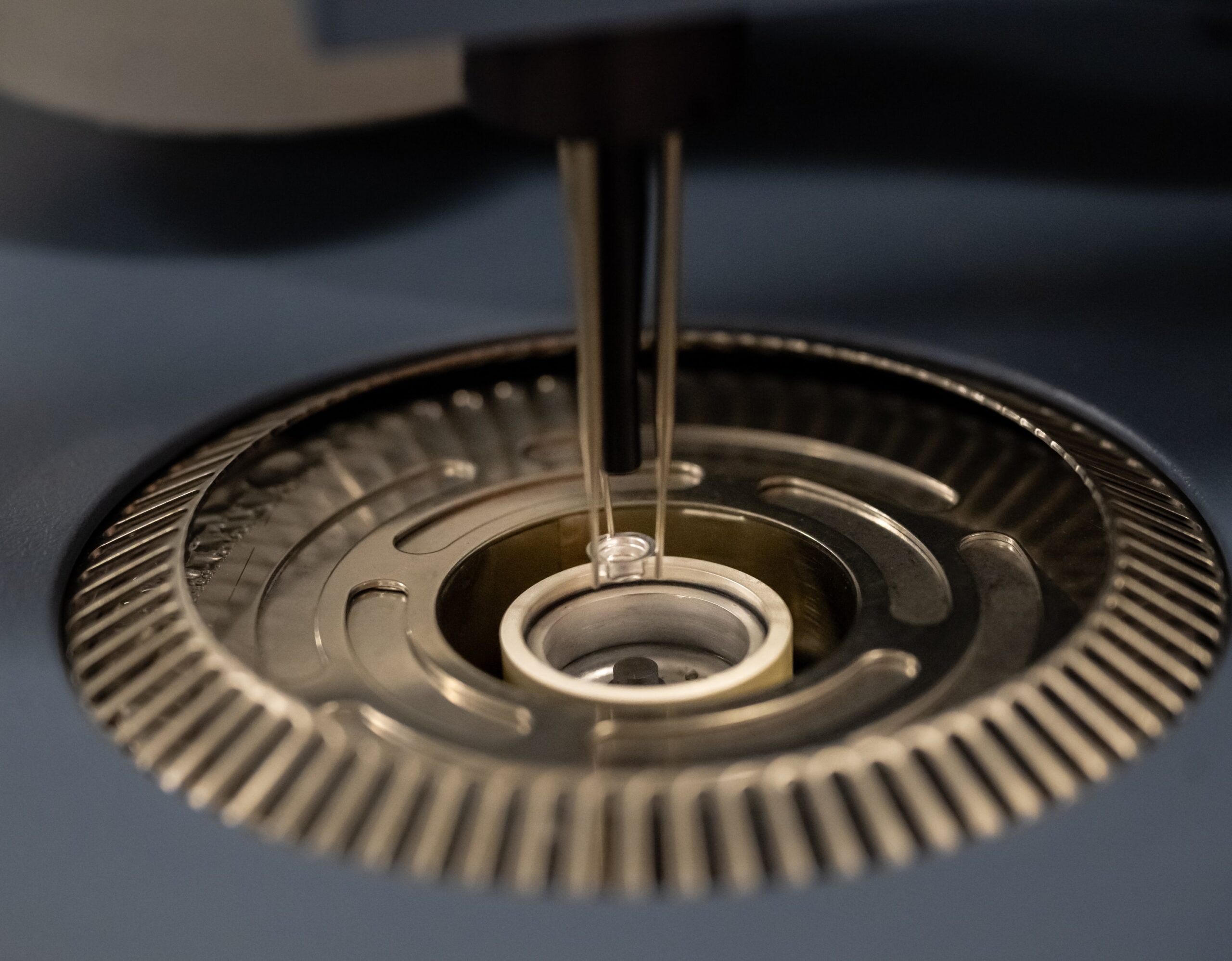

To deliver precise, reliable rheological data, our laboratory is equipped with advanced instrumentation, including the Discovery HR 20 Rheometer. This system accurately tests everything from low-viscosity fluids to highly viscous thermoplastic melts, helping you gain deeper insight into:

- Fluids: Characterize emulsions, suspensions, or lubricants, understand flow behavior and stability with precision.

- Thermoplastics: Analyze melt viscosity, elasticity, and processing performance for polymers that shape your products.

- Product Development: Fine-tune formulations, develop or compare with detailed viscoelastic data.

- Quality Assurance: Verify consistency across batches, from raw materials to finished goods. Predict performance in end-use applications. Optimize processing conditions (injection molding, extrusion, etc.).

Experience

- Consumer products

- Plastic resins destined for extruded film applications

- Adhesives, sealants and coatings including construction materials, sealants, caulks, adhesives, and asphalt

- Heat transfer fluids and lubricants

- Polymers, copolymers, and polymer blends

Approaches

Rheology testing for polymers and other complex fluids is often conducted using parallel plate or cone-and-plate geometries. The data provided by rheological testing is more representative of processing than Melt Flow Rate (MFR), a different thermal test.

We most commonly test ASTM D4440, the Standard Test Method for Plastics: Dynamic Mechanical Properties Melt Rheology and can also tailor testing to your specific protocols.

Sample Considerations

Our laboratory technicians can convert a product into a suitable sample by using our sample preparation equipment, you can provide:

- Liquids

- Pastes

- Solids (in the form of pellets, powder, or films.)

A typical sample volume needed for rheological testing is a disk with dimensions of approximately 1-inch diameter and 1/8-inch in thickness. A sample size of several hundred milliliters, a few fluid ounces, or 5-10 grams is typically sufficient. If your sample material is in short supply, don’t worry. Our scientists will work with you to ensure your sample is used in the most efficient way.

Contact an expert to discuss your specific testing needs and associated sample considerations.