Background

The most important attribute of a polymer material is its basic chemical structure. Polyolefins, polyesters, polyurethanes, and polyamides are some examples of polymer materials. The composition of the polymer determines basic inherent properties that can be expected, such as chemical compatibility, softening temperature, melting temperature, and mechanical properties, for example.

Next in importance is molecular weight and molecular weight distribution. There are methods of analysis that reveal an average molecular weight. Melt flow rate, melt flow index, membrane osmometry, end-group analysis, and dilute solution viscosity are a few examples.

In many applications, however, it is highly advantageous to determine the molecular weight distribution of the polymer, not simply a single average representation of the molecular weight. This is because the molecular weight distribution has a significant effect on the mechanical properties and processing characteristics of the polymer.

One of them most common methods used to determine the molecular weight distribution of polymers is gel permeation chromatography (GPC) which is also known as size exclusion chromatography (SEC). To evaluate a polymer using GPC the polymer must be soluble and is filtered to remove insoluble components such as fillers and additives.

Molecular Weight Determination of Polyolefins

Many solvents are routinely used to dissolve polymer materials; some are rather common whereas others are more exotic, expensive, and dangerous to work with. There are some polymers, polyolefins for example, that are not soluble at room temperature and therefore require special solvent selection and dissolution at a high temperature. This means conventional GPC is not an adequate analytical technique. Rather, High Temperature Gel Permeation Chromatography (HT-GPC) must be employed to ensure the successful determination of molecular weight.

A common concern of plastic processors across a variety of industries is the ability to switch suppliers with certainty that the new material will perform as required. For polyolefin resins, using HT-GPC is an ideal analytical approach to this testing need.

Applications of HTGPC

Example 1: Polyolefins

Those familiar with GPC analysis of polymer materials know that polyolefins of reasonable molecular weight (as opposed to “waxes”) require elevated temperature to obtain polymer solutions that can subsequently be analyzed. Polyolefins are one group of polymers that require HT-GPC. The determination of their molecular weight distribution is important because polyolefins are used in many demanding applications, such as medical products and food packaging.

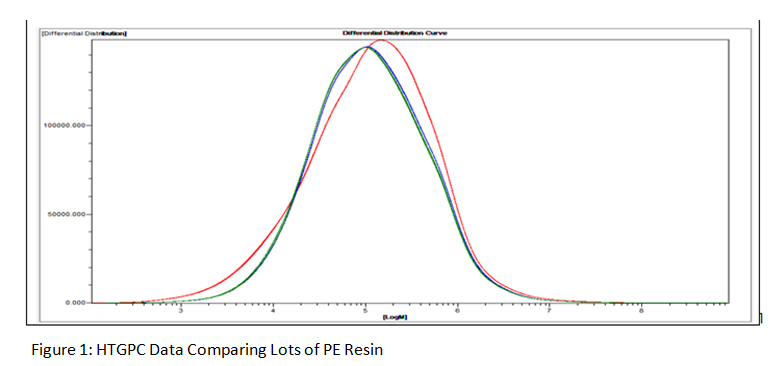

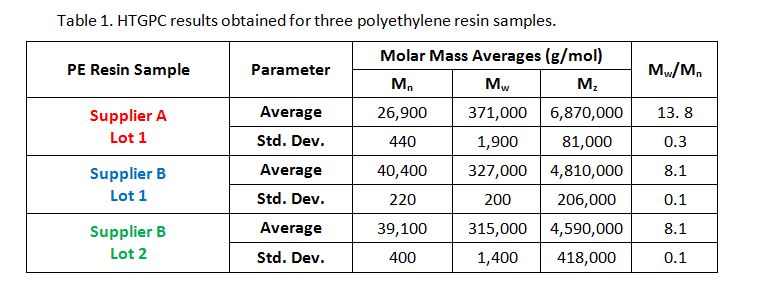

Lot-to-lot variability and the potential to qualify a second source of polyolefin resin is of interest to many materials selection teams. In that case HT-GPC is the proper analytical approach. Shown below is the HT-GPC molecular weight distribution that was obtained for a lot of polyethylene (PE) resin obtained from Supplier A (red data set) compared to two lots of resin from Supplier B (blue and green data set). Differences are noted for the PE resin offered by Suppliers A and B and a very high level of lot-to-lot uniformity is being provided by Supplier B. This high level of uniformity is able to be documented in part because of the precision and repeatability of the HT-GPC analyses as implemented by our laboratory. The summary table provides the numerical data that were obtained and would be relied on by the materials selection team in assessing the ability of Supplier A to be an alternate supplier.

Example 2: Polypropylene Resin Samples

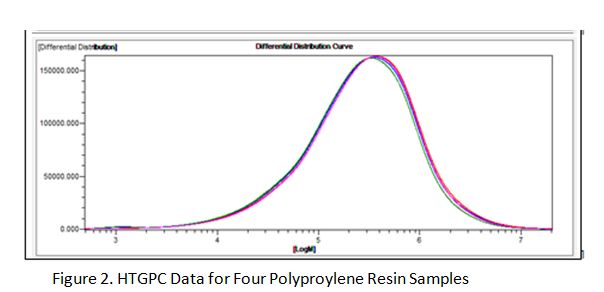

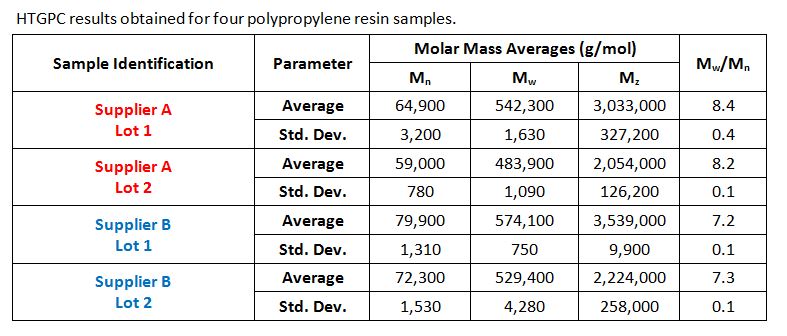

A similar HT-GPC analysis for four polypropylene resin samples is shown below (Figure 2). The molecular weight distributions are very similar among the samples. However, the polydispersity, or the ratio of the two molecular weights, of Supplier B is narrower than that of Supplier A. There is nothing inherently right or wrong about the Mw/Mn value but rather the important key, when trying to determine if a material is a proper substitute, is consistency with that number. The summary table provides the numerical data that allows for the determination of Supplier B being a drop-in replacement for

Supplier A.

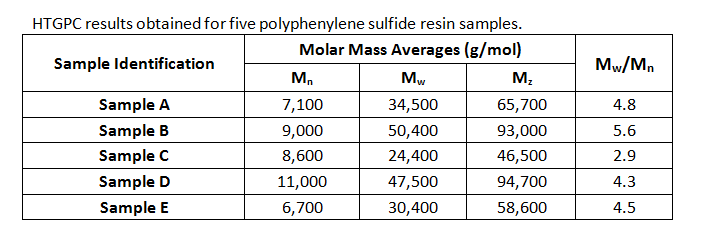

Example 3: Polyphenylene Sulfide

Polyphenylene sulfide (PPS) is a high temperature performance polymer that is used in a variety of engineering applications requiring very high softening temperature, solvent resistance, and thermal stability. Gears, pump heads, automotive parts, and electrical components are some of the applications that utilize these important characteristics of PPS. The ability to process PPS plastic parts and attain the required mechanical properties is strongly influenced by the lot-to-lot uniformity of the PPS resin that is supplied to the molder. HT-GPC is an excellent analytical method for obtaining objective data sets that can be used by the material selection team to audit their supplier.

The table below shows the molecular weight parameters that were measured for five lots of PPS resin. In this case, the standard deviation that was calculated for each pair of analyses ranged from 0.00 to 0.04, rounded to 0.0, and therefore has not been shown in the table of data.

Summary

The ability to obtain precise and highly repeatable molecular weight distributions for polymers is vital to informed decision making. Finding alternative suppliers, advancing a root cause analysis as part of failure investigation, and assuring lot-to-lot uniformity are examples that benefit from HT-GPC.