We like to regularly get out of the office and go visit our clients on-site. We think this face to face interaction is important and really love to have conversations in person; we think it is tremendously  valuable. On one such visit our CEO, Jim Rancourt, was meeting with a client and handed him our 1-page services sheet. Since we are a polymer testing company, we thought we’d be clever and deliver it on a medium that is relevant to who we are, a plastic handout. The client took the sheet, looked at it, and quickly commented, “This stinks.” No, he wasn’t referring to the design of the handout or the words on the sheet; he meant it actually had an odor. Our CEO took a whiff and had to agree, our sales sheet does stink! If you know anything about our CEO and our team you know that we are curious bunch. Jim couldn’t accept that the marketing sheet was stinky without understanding why. And thus began our investigation into our stinky sales sheet.

valuable. On one such visit our CEO, Jim Rancourt, was meeting with a client and handed him our 1-page services sheet. Since we are a polymer testing company, we thought we’d be clever and deliver it on a medium that is relevant to who we are, a plastic handout. The client took the sheet, looked at it, and quickly commented, “This stinks.” No, he wasn’t referring to the design of the handout or the words on the sheet; he meant it actually had an odor. Our CEO took a whiff and had to agree, our sales sheet does stink! If you know anything about our CEO and our team you know that we are curious bunch. Jim couldn’t accept that the marketing sheet was stinky without understanding why. And thus began our investigation into our stinky sales sheet.

Our Senior Chemist, Jason Smith, tackled this odor analysis project. First, he took samples of all the materials that composed the sheet to which we had access The handout was printed on a clear multilayer plastic sheet which we identified as PET/acrylate or methacrylate multilayer plastic roll stock, using Fourier Infrared Transform Spectroscopy (FTIR). After the handout was printed, the print company applied spray paint to the back of the sheet in order to create an opaque surface on which the print would be legible. We were able to obtain the following samples for analysis:

- Cardboard box

- The sales sheets are housed in a cardboard box

- Market sheets unwrapped in box

- A portion of the handouts were sitting unwrapped in the cardboard box, stacked on one another (back of sheet was painted with white Valspar spray paint)

- Market sheets sealed in plastic wrap

- A portion of the handouts were sitting in the cardboard box but shrink-wrapped in plastic

- PET/acrylate or methacrylate multilayer plastic roll stock

The method used to perform this analysis was Headspace Gas Chromatography with Mass Spectrometry (GC-MS). This method was selected because it is used to analyze volatiles, which are the light molecular weight compounds that evolve off a sample. Approximately 1 gram of each sample was incubated for two hours at 60°C in a 20 mL headspace vial. Heating at 60°C doesn’t destroy the sample and allows the volatiles to escape into the headspace. The headspace of each vial was sampled and injected onto a GC-MS system for separation and identification of volatile compounds. GC-MS separates each individual component of a mixture based on the size of the molecule and/or how the molecule interacts with the GC column. The size of the molecule has a direct bearing on how quickly it is able to pass through the column. Once the various compounds are separated using the column they are identified with the mass spectrometer. Each component has a “fingerprint” that the spectrometer is able to read.

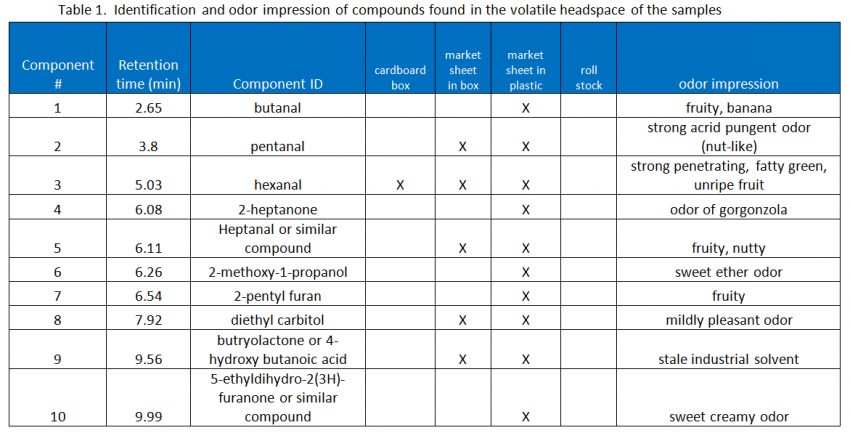

After the compounds were identified, research was done to understand the known odor impression of the various compounds. Numerous compounds were identified within the four different samples. However, only ten of those compounds were known to have a defined odor impression.

Table 1 displays the identification and odor impression of compounds found in the volatile headspace of the samples. As you can see, the cardboard box alone and the plastic roll stock did not contain many compounds with odor impressions—only one was found in the cardboard, and none were found in the plain stock. However, the final sales sheet had a host of compound with associated odors. The sales sheet that was wrapped in plastic had all ten compounds that were identified as having an odor impression.

Although individual compounds may be attributed to an unpleasant odor impression, the real culprit is the combination of the various odors. For example, combining the smell of “stale industrial solvent” with “odor of gorgonzola” and “fruity banana” is just begging for a smelly combination. The human nose would not be able to separate and differentiate between the various smells.

We were able to determine that the plastic in and of itself did not have a smelly odor, when heated at 60ºC for two hours. We were also able to determine that the cardboard did not contribute to the smelly odor of our sales sheet. The stinky smell is attributed to the spray paint backing of the sheet.

Further analysis could be conducted to understand the interaction between the spray paint backing and the PET/acrylate or methacrylate material. It is possible that changing the material of the sheet would not invoke such pungent odors. To further test this idea, we would need to spray several different stock materials with different types of paints, with at least one low odor variety. Our noses would perform the evaluation, which would be a very sensitive evaluation because the human nose can detect some compounds at limits below a part per billion range. Wouldn’t it be cool if in the future, we distribute services sheets that smell like fresh flowers and cinnamon rolls…you never know what we’ll be up to next!