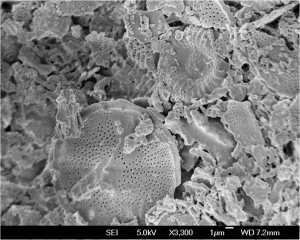

What you are looking at isn’t from outer space it’s actually earth– a 3,300 magnified view of diatomaceous earth to be specific. Our Microscopy Lead, Jonny Angle, captured this image while working with our Scanning Electron Microscope. Diatomaceous earth is commonly used in applications like filters, reinforcement for some plastics, an absorbent, and even in toothpaste! The fine white powder comes from the fossilized remains of diatoms or, hard shelled algae.

What you are looking at isn’t from outer space it’s actually earth– a 3,300 magnified view of diatomaceous earth to be specific. Our Microscopy Lead, Jonny Angle, captured this image while working with our Scanning Electron Microscope. Diatomaceous earth is commonly used in applications like filters, reinforcement for some plastics, an absorbent, and even in toothpaste! The fine white powder comes from the fossilized remains of diatoms or, hard shelled algae.

Optical microscopy vs. scanning electron microscopy

The science behind scanning electron microscopy is amazing to say the least. Optical Microscopy uses natural light to magnify a sample area and is able to do so at a range of 10-1,000 times magnification. These are microscopes that are often used in high school science classes, for example. They are affordable, generally small sized, and user friendly. In contrast, a Scanning Electron Microscope uses a concentrated beam of electrons to image a sample area. The SEM provides a much better depth of field and resolution than Optical Microscopy. In order to operate an SEM with skill and precision it takes hours upon hours of training behind the microscope to get to the level of clarity and precision needed.

How it works

The scanning electron microscope uses a highly focused electron beam to scan across a sample’s surface. The electron beam scans in and interprets three signals: secondary electrons, backscattered electrons, and X-rays. The intense magnification and high resolution is made possible by the small size of the primary electron beam. The sample being imaged is placed in a vacuum to make sure the electron beam stays focused and does not interact with particles in the air then, when the beam hits the surface of the sample, secondary electrons are emitted and create an easily interpreted topographical image of the sample. “X-rays are also released from the surface of the sample that carry a unique energy signature that is specific to elements found in the sample. These X-rays are detected with the EDS detector to give elemental information about the sample,” explains PSI resident microscopy expert Jonathan Angle. The sensors and systems within the electron microscope take care of the data interpretation but getting the data in the first place is a whole different story and it’s about one word: practice.

Training to be an SEM expert?

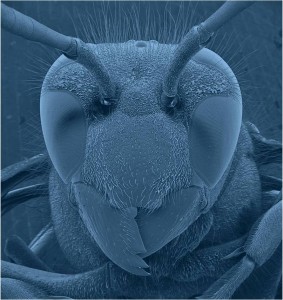

The SEM/EDS process can be summarized into three categories; learning how to prepare your sample, learning how to operate the instrument and learning about behaviors of various materials while performing SEM. In order to operate an SEM with skill and precision it takes hours upon hours of training behind the microscope to get to the level of clarity and precision needed. The scientists at PSI have their own creative way of honing their microscopy skills and they do it with insects! Insects turn out to be the perfect objects to practice with the SEM on because while they are extremely small they have very complex yet predictable structures. Operators are able to focus not only at low magnifications but allow them to zoom in and focus at any multitude of magnifications.

In a microscopic way — pardon the pun — Polymer Solutions can support the very serious need for future scientists. PSI Founder and CEO Jim Rancourt told the Roanoke Times:

“Science I view as also critical to society. There was a story in USA Today saying we need more clean water, even in the U.S. […] Solar energy, in order to be implemented, needs materials that don’t currently exist in a form that can be produced in large enough quantity at low enough cost. […] We also need more modes of transportation.”

And we could all use more images of bugs and biohazards, magnified into jaw-dropped works of art. Because it’s still a thrill for the adults as well as the kids to marvel at this unseen world. “Seeing how the ‘unseen’ functions fit together to make a large scale object is incredible to witness,” says Angle.