It’s no secret that we love solving problems. So when our client, who was in the business of selling children’s toys, approached us with their perplexing problem we were excited for the challenge. Our client was unable to continue the distribution of one of its toys – there was a defect. On the wrist strap portion of the toy white crystals were blooming to the surface during the manufacturing process. We were tasked with getting to the bottom of their blooming crystal mystery.

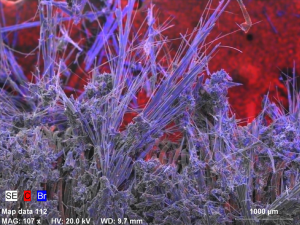

We had to deter mine what the crystals might be. We used Scanning Electron Microscopy (SEM) to obtain images of the crystals. By also applying Energy Dispersive Spectroscopy (EDS), we created an elemental map on those images in which each color represented a different element. From there, it was determined the crystals were bromine, which is commonly used as a flame retardant. This gave the client the information they needed to address the issue, prevent recurrence, and most importantly ensure the safety of the children using the toy. We got to the bottom of the blooming crystal mystery and thoroughly enjoyed being their problem solver. So we solved the problem and closed the lab notebooks, and we’re here to share with you a little more information about flame retardants.

mine what the crystals might be. We used Scanning Electron Microscopy (SEM) to obtain images of the crystals. By also applying Energy Dispersive Spectroscopy (EDS), we created an elemental map on those images in which each color represented a different element. From there, it was determined the crystals were bromine, which is commonly used as a flame retardant. This gave the client the information they needed to address the issue, prevent recurrence, and most importantly ensure the safety of the children using the toy. We got to the bottom of the blooming crystal mystery and thoroughly enjoyed being their problem solver. So we solved the problem and closed the lab notebooks, and we’re here to share with you a little more information about flame retardants.

What types of products require flame retardants?

- Every day we are surrounded by products that contain flame retardants. Nearly all industries must consider flame retardants in their formulations whether they are required for consumer safety purposes or to protect the integrity of the product–and therefore the financial interests of the manufacturer. Flame retardants are a group of chemicals added to materials or products to prevent or slow the spread of fire. Flame retardants are usually grafted into the final polymer, part of an additives package, or a coating on a product. Finished products ranging from ceiling tiles to sofas, children’s toys to circuit boards all contain flame retardants. Flame retardants have an important role within the electronics, textile, furniture, clothing, construction, and children’s toy industries.

- Even when a manufacturer believes they have a winning system it must be verified. For example, it is possible that incorporating a flame retardant as part of an additives package will disrupt the performance of other additives, rendering them ineffective. The correct balance must be found which provides the benefits of the flame retardant without disrupting other performance characteristics or posing safety risks due to toxicity.

What are the common analytical needs related to flame retardants in consumer products?

- Composition Analysis—determining that the composition is as expected or as desired

- Declarable Substance Testing, according to regulations such as REACH and RoHS

- Competitive product analysis

- Deformulations

- Failure Analysis

- Coating Analysis of Intumescent Coatings. Looking at thickness, uniformity.

So take a moment to look around you. Chances are you’re surrounded by objects that contain flame retardants. Whether it’s something as small as a child’s toy or as large as a construction project, flame retardants provide manufacturers with a way to make their products, and your world, a little bit safer.