Summary

A company within the Medical Device industry contacted Polymer Solutions Incorporated (PSI) regarding a failure analysis of an acrylonitrile-butadiene-styrene (ABS) part. Microscopic evaluation was requested with the goal of determining the mode of the failure. The client submitted one sample that had failed.

Optical Microscopy

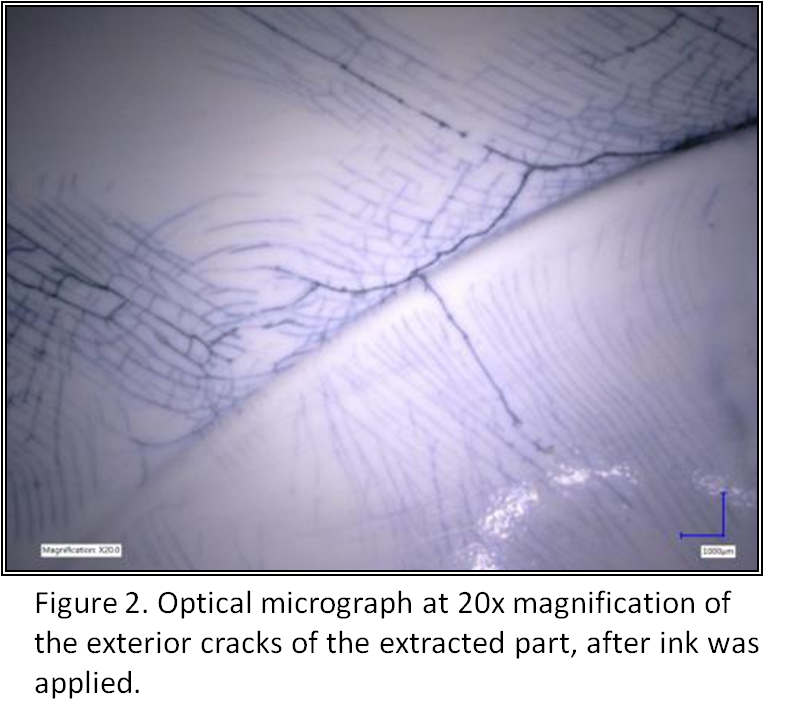

The sample arrived with the area of interest marked by the client (Figure 1). Prior to sample preparation, the failed part was photographed. The sample was then analyzed by optical microscopy, utilizing a Keyence VHX-5000 Microscope. A handheld rotary tool with a clean grinding disk was used to cut into the sample and make the area of interest more accessible. While the cracks were visible to the eye they were not easily documented with the microscope. To overcome this, ink was applied to the sample, thus making the cracking more visible which is shown in Figures 2 and 3.

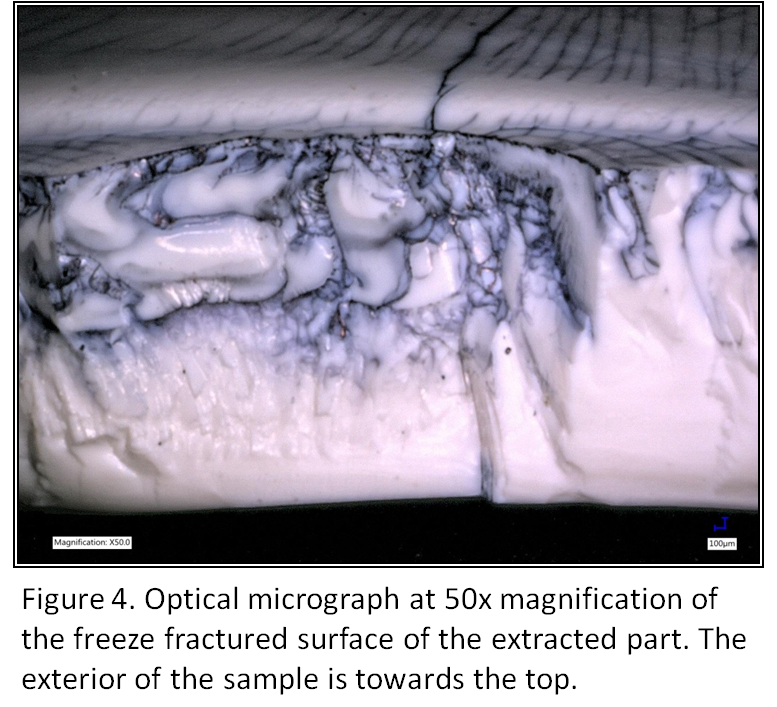

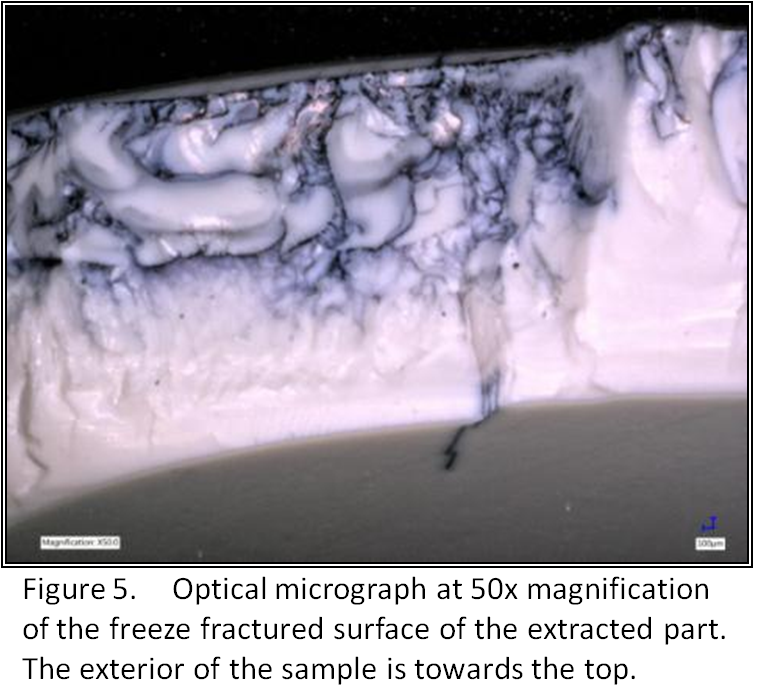

To determine the origin of the cracking and direction of propagation, the sample was freeze fractured in liquid nitrogen along the existing main cracks. After freeze fracture, both sides of the cross section were imaged, and it was determined that the crack originated on the outer surface and propagated towards the interior surface. Figures 4 and 5 show images at 50x magnification of the fracture surface, which exhibits the characteristic thumbnail patterns typically generated by Environmental Stress Cracking (ESC).

Scanning Electron Microscopy (SEM)

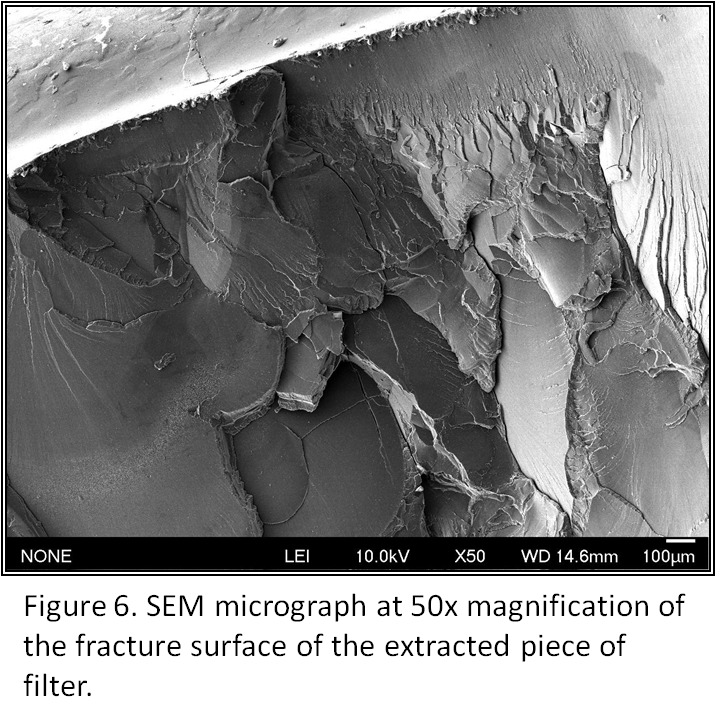

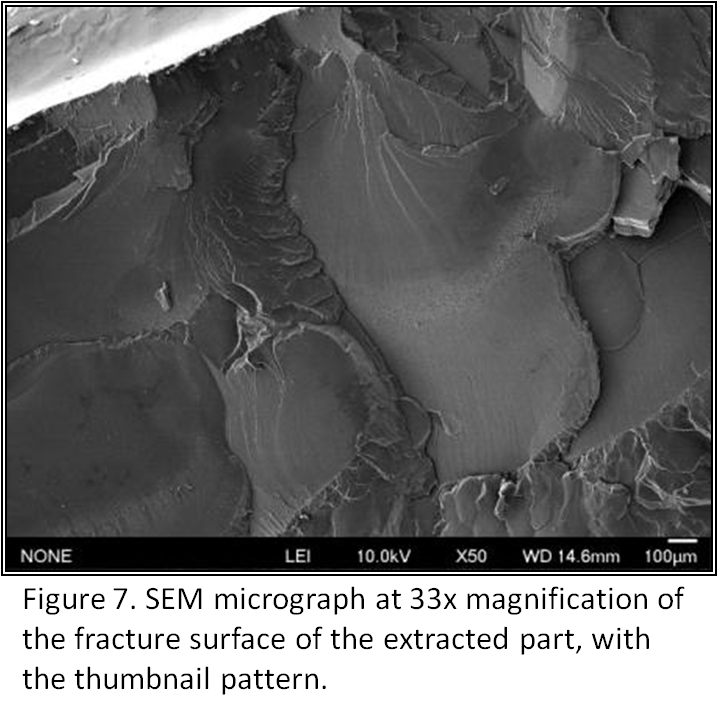

In order to gain additional information about the mode of failure, SEM was performed. The specimen, which had been previously examined using optical microscopy, was mounted on an aluminum SEM stub and sputter coated with a thin layer of gold, to prevent electrical charging. Fractographic analysis of the fracture surface was performed, and SEM micrographs are shown in Figures 6 and 7. Note that the exterior of the surface is located towards the top of the images.

The sample exhibited large thumbnail patterns originating from the exterior of the pipe. The thumbnails exhibited a glassy smooth brittle failure pattern which is indicative of slow crack speed and is often associated with Environmental Stress Cracking (ESC). The thumbnail patterns continued until the cross-section was reduced enough to fail mechanically.

Conclusions

Optical and scanning electron microscopic analyses revealed features consistent with environmental stress cracking of the ultrafilter. The orientation of the features indicates the ESC originated from the exterior surface of the sample. ESC occurs when a material is weakened by a chemical agent and then physical stress is applied, resulting in a failure. Confirming this failure mode and directionality of the failure allowed our client to proceed with a systematic root-cause analysis to determine what led to the ESC of the part made from ABS material.